In-Die Riveting Progressive Die for Sheet Metal Hinge

Specification:

Part Name: Sheet Metal Hinge

Die Type: Progressive Die with Riveting

Product Material: SPCC;

Thickness: 2.0mm;

Die Materail:SKD11,Cr12mov, 45#;

Spare parts: MISUMI;

Die Size: 1370*570*510.5mm

Exported to:Russia

Engineering Highlights:

Equipped with :

Equipped with XYZ three-axis fine-tuning platform for automatic riveting equipment to precisely control rivet position.

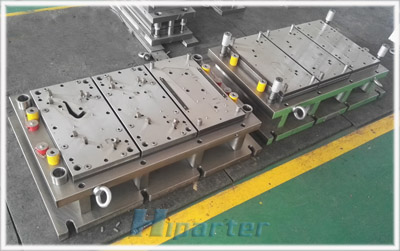

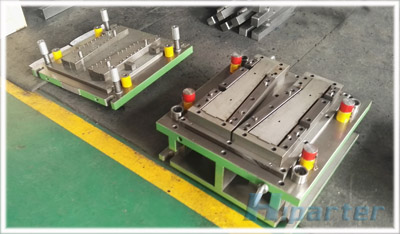

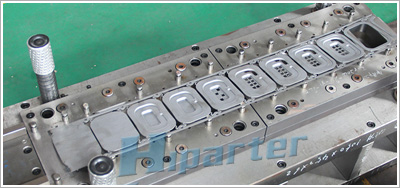

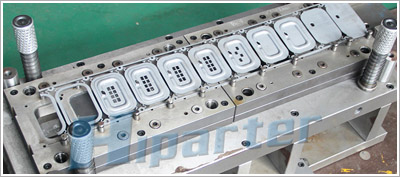

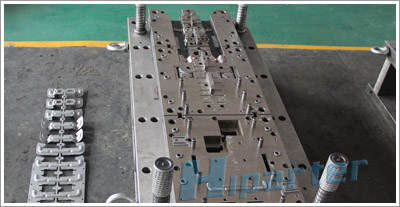

Bumper Metal Spare Parts Transfer Die & Stage Die

1)Product Used: Bumper spare parts

2)Product Material: Cold sheet

3)Material Thickness: 2mm;

4)Die type: transfer die + stage die

5)Stages Quantity: 4

6)Tool quantity: 3

7)Tool Material: Cr12mov;

8)Machining equipments: WEDM-LS, CNC,EDM,etc.

9)Spare Parts: PUNCH,Misumi standard;

10)Die life: 300,000 shots;

11)Quality cerficated: ISO 9001:2008;

12)Lead time: 50 days;

13)FOB Qingdao;

14)Payment: TT;

15)HS code: 8207300090

16)Delivery: By sea.

17)Exported to: Ecuador

Related stamping dies:

Try stamping dies:

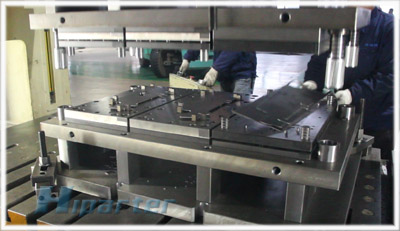

We have about 20 sets of punching machines.

Before delivery the dies, we try them in workshop to guarantee the dies can run smoothly.

Split dies drawings, mark processing methods and control processing quality.

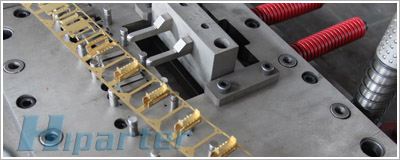

Sheet Metal Cable Clamp Progressive Stamping Die

1)Product Used: Porsche Cable Clamp

2)Product Material: HC260LA

3)Material Thickness: 1.5mm;

4)Die type: Progressive die;

5)Stages Quantity: 15

6)Cavity: 1

7)Tool Material: SKD11,Cr12mov;

8)Machining equipments: WEDM-LS, CNC,EDM,etc.

9)Spare Parts: PUNCH,Misumi standard;

10)Die life: 1,000,000 shots;

11)Quality cerficated: ISO 9001:2008;

12)Lead time: 50 days;

13)FOB Qingdao;

14)Payment: TT;

15)HS code: 8207300090

16)Delivery: By sea.

17)Exported to: UK

Related progressive die:

We have about 20 sets of punching machines.

Before delivery the dies, we try them in workshop to guarantee the dies can run smoothly.

Dies Processing:

Split dies drawings, mark processing methods and control processing quality.

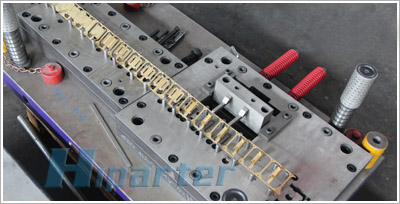

Citroen 405ECS Motor Carbon Brush Holder Progressive Tool

Made in Qingdao,China.

Used in Citroen 405 ECS;

Part Material: Cuzn;

Material Thickness:0.6mm;

Stages Quantity:17;

Toold Material: SKD11,Cr12mov;

Spart Parts: PUNCH,Misumi standard;

FOB Qingdao;

Payment: TT;

Related progressive die:

In order to guarantee the precision of the sizes, we use 17 stages to realize it. There are sereral idle stages for maintainance when necessary.

Use sliders to curle the parts.

Advantages of service:

1. Rich experience;

2. Resonable die structure to save stamping die cost;

3. Quick-change system, you can repair or maintain the dies conveniently when the dies on press machine;

4. In-house for all the machining work;

5. One-stop service.

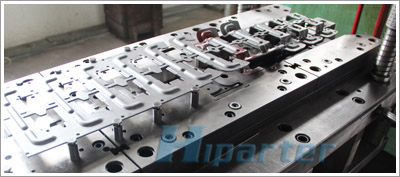

Automotive SPHC Metal Nozzle Progressive Die

Part Name:10HZ UPPER/LOWER NOZZLE

DTR for FCA;

Die Type: 2 Progressive Die+1 Singe Stage Die;

Shaping Mode: Punching Mold;

Product Material: SPHC;

Thickness:1.6mm;

Die Materail:SKD11,Cr12mov, 45#;

Spare parts: MISUMI;

ISO9001:2008;

Trial Sample Picture:

Related Progessive Die:

In order to improve the productivity, these parts are produced by progressive dies and single stage dies. The upper and lower part are in the same forming die to reshape the outside shape, and realize the sizes within tolerance.

Check And Acceptance:

Customer from MOBIS check the stamping dies on spot.

Welcome you visit Hiparter!

Bumper Side Support Bracket Progressive Die

Product Material: SGACC;

Thickness:1mm;

Die type: Progressive die;

Stages:14;

Die Material:SKD11;

Spare Parts: MISUMI standard.

Rich experience over 13 years;

ISO9001:2008;

For HYUNDAI cars.

Related Stamping Die Pictures:

OUR ADVANTAGES:

Rich experience from 2003;Reasonable die structure to save cost;

Precision machining to guarantee the quality;

Communication on time;

Guarantee delivery time;

Many years to exported dies and moulds.

Use Fixture to Check the Metal Bracket:

UPPER/LOWER NOZZLE STAMPING DIE

DTR for FCA;

Shaping Mode: Punching Mold;

Product Material: SPHC;

Thickness:1.6mm;

Die Type: Progressive Die+Singe Stage Die;

Die Materail:SKD11,Cr12mov, 45#;

10HZ UPPER/LOWER NOZZLE

ISO9001:2008;

HS code:8207300090;

Spare parts: MISUMI;

Related Dies Pictures:

Metal Strip for Progessive Die:

Check And Acceptance:

Customer from MOBIS check the stamping dies on spot.

Welcome you send us samples or drawings to inquiry. We will quote you the best price with high quality on time.

HYUNDAI Bracket FR Bumper Side SUPT LH/RH

Product Material: SGACC;

Thickness:1mm;

Die type: Progressive die;

Stages:14;

Die Material:SKD11;

Spare Parts: MISUMI standard.

Rich experience over 13 years;

ISO9001:2008;

For HYUNDAI cars.

Related Stamping Die Pictures:

OUR ADVANTAGES:

Rich experience from 2003;Reasonable die structure to save cost;

Precision machining to guarantee the quality;

Communication on time;

Guarantee delivery time;

Many years to exported dies and moulds.

Use Fixture to Check the Metal Bracket:

Automotive Oil Bracket Stamping Die

Die Specification:

- Die No.: HPD20161001;

- Part Material: SAPH440;

- Material Thickness: 2.6mm;

- Unfolded sizes: 186*67;

- Die sizes: 1150*500*440;

- Press Machine: 250T;

- Die Type: Progressive Die;

- Cavity: 2;

Related progressive die:

This die is made in January, 2016;

Advantages of service:

- Rich experience from 2003;

- ISO9001:2008 by SGS;

- Resonable die structure to improve die quality;

- Quick-change system, you can repair or maintain the dies conveniently when the dies on press machine;

- Standard die with detailed 2D/3D drawings;

- In-house for all the machining work;

- One-stop service;

- Less scratch,less burrs;

Production in batch:

Before delivery the stamping die, we'll produce the parts in a little batch, so that we can guarantee the die will work with no problem in our customer's workshop.

For some special part material, customer will offer us the matrial to try the die.

Detailed inspection report will be made.

Package and delivery:

When delivery the die, the parts will be shipped with dies to customers with detailed 2D/3D drawings.

Deliveried from Qingdao Port.

Seat Recliner Mechanism Metal Part

Parameter:

1) Part Material: SPCD270;

2) Material Thickness: 2mm;

3) Unfolded Size: 341*218*2.0;

4) Stages: Drawing, Blanking,Flanging,Side Pirecing;

5) HS Code: 820730090;

6) Spare Parts: PUNCH standard;

7) Made in Qingdao, China.

Die Trial Plates:

Before delivery the stamping dies, we will paint it with the color you need.

Also, we will oil it to avoid rust in the long time of sea freight.

Small Batch:

We will produce a small batch of parts for you to test the dies. And gurantee the stamping dies can produce the parts in your factory without any problem.

Related Stamping Die Picture:

The dies are suitable for 80T,160T Press machine.

Made in March, 2013;

Find What You Want

Home Appliance Parts

Progressive Dies

Deep Drawing Dies

Tags

Latest Home Appliance Dies

-

Water Heater Stamping Die

Read 7358 times

Famous on Water Heater stamping dies --Hiparter. 1. Great team with 13 years' experience; 2. ISO9001:2008; 3.Reasonable die structure to…

Famous on Water Heater stamping dies --Hiparter. 1. Great team with 13 years' experience; 2. ISO9001:2008; 3.Reasonable die structure to… -

High End Washer Front Panel Punching Tool with Surface Treatment

Read 4499 times

1)Tool type: Stage Punching Tool 2)Product Material: Cold steel, Galvanized steel, Stainless steel, etc. 3)Die material: SKH-9, DC53, SKD11, Cr12Mov,…

1)Tool type: Stage Punching Tool 2)Product Material: Cold steel, Galvanized steel, Stainless steel, etc. 3)Die material: SKH-9, DC53, SKD11, Cr12Mov,… -

Washing Machine Front Plate Part

Read 8062 times

Front Plate of Washing Machine (7kg) 1) stamping die company with our own pressing plant in Qingdao since 2003. 2)…

Front Plate of Washing Machine (7kg) 1) stamping die company with our own pressing plant in Qingdao since 2003. 2)… -

Water Heater stamping parts

Read 7112 times

Famous Water Heater stamping parts manufacturer--Hiparter. 1. 9 years' experience in the field of stamping dies 2. ISO9001:2008 3. With…

Famous Water Heater stamping parts manufacturer--Hiparter. 1. 9 years' experience in the field of stamping dies 2. ISO9001:2008 3. With…